一、 概 述

Ⅰ、Summary

CFZ型泵为船用卧式自吸污水泵用于船舶生活污水处理装置中粉碎原污水。水温为常温,泵的过流部件均采用铸铜件、不锈钢材料。故本泵也可用于输送海水。

The CFZ type pump is marine horizontal self-priming sewage pump ,which is used to crush the raw sewage in the ship sewage treatment plant. Water temperature to be room temperature, the pump flow parts are made of bronze pieces or stainless steel materials. This pump can also be used to transport water.

二 、结构型式

Ⅱ、Stureture

本泵为带刀离心泵。粉碎刀安装在泵体内,与叶轮上的带刃叶片组合成粉碎刀组。污水残渣经过刀组的剪切,并且多次循环,被粉碎成细小颗粒的污泥残渣。泵的轴封采用机械密封,泵体顶部和底部分别装有注水、放泄的螺塞。

This pump is centrifugal pump with the knife. Crush knife installed in the pump body and impeller edged blade into the crush blade unit. Sewage residue after shear knife, and recycled many times, was crushed into fine particles of sludge residue. Pump shaft seals use mechanical seal, pump top and bottom, respectively,equipped with water injection plug and the drain plug.

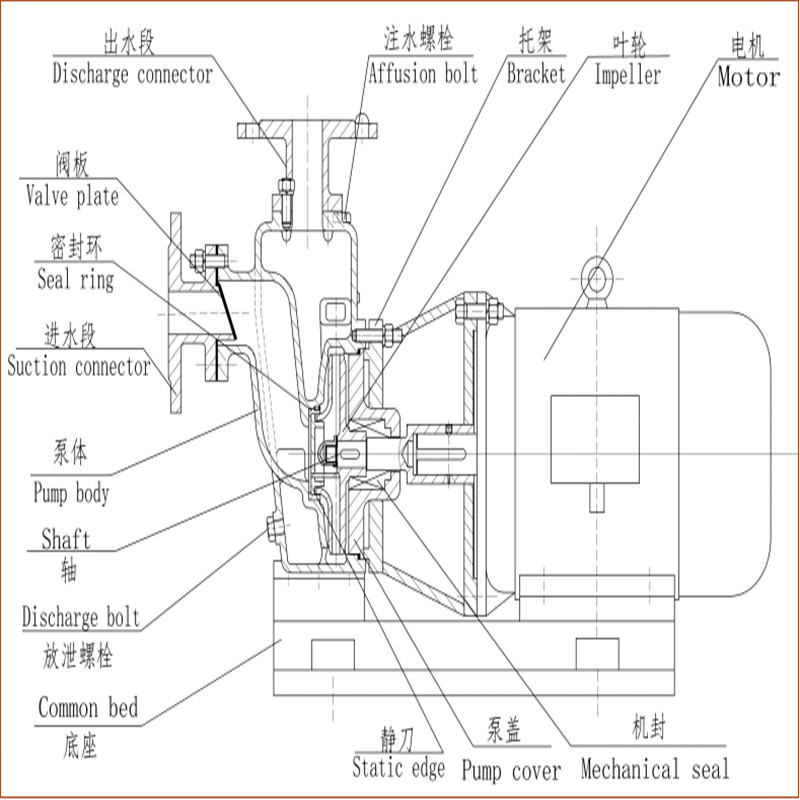

泵的结构图见图1:

Stureture drawing of the pump:

图1 Fig.1

三、装配与拆卸

Ⅲ、Assembly and disassembly

(一) 装配:

(一)Assembly :

1.预先将纸垫、密封圈等分别放置在相应的零件上;

1.Put spacer and seal ring in the relevant part;

2.将密封环、静刀装入泵体内;

2.Put the seal ring, static knife into the pump body;

3.将泵轴套在电机轴上,然后将托架与电机连接,拧紧螺母;

3.The shaft sleeve fitted on the motor shaft, and then the bracket is connected to the motor, tighten the nuts;

4.将泵盖套在泵轴上,装上叶轮,装上机械密封,拧紧叶轮螺母;

4.Pump cover fitted on the pump shaft, impeller fitted, mechanical seal fitted ,tighten the impeller nuts;

5.将泵体与托架连接,拧紧螺母;

5.Pump and bracket to be connected, tighten the nuts;

6.装好进水段和出水段,拧紧螺母;

6.Fitting the suction connector and the discharge connector, tighten the nuts;

7.最后将泵组和电机安装在公共底座上。

7.Finally, the pump and motor are mounted on a common base.

(二)拆卸:

泵的拆卸顺序与装配顺序相反。

(二) Disassembly

The disassembly order is contrary to the assembly order.

四、安装

Ⅳ、Installation

泵的安装好坏对泵的运行和寿命有重要影响,所以安装和校正必须仔细。

The installation of pump could affect the running and service life of pump. Therefore, it is necessary to be careful during installation and adjustment.

1. 检查水泵和电机有无损坏,检测基础尺寸,准备工具。

1. Inspect the motor and pump to check if there is any failure and inspect the main dimension,prepare tools.

2. 把泵组水平地安置在基座上,用螺栓锁死。

2. Install pump on the installation base, and loosen the bolt.

3. 泵进口处装接管时必须有一可拆短管(约200mm)以便清除吸口的堵塞物。

3. The pump inlet must have a removable short pipe (approximately 200mm) in order to eliminate the obstruction of the suction.

4. 安装管路时,必须使管路重量、弹性力等不得直接加在水泵上。

4. Make sure that the weight and flexible force of pipe do not act on pump directly while installing pipe.

五、 使用及维修保养

Ⅴ.Service and Maintenance

使用要求

Requirements of service

1. 启动前,必须先盘动泵轴,确信转子无卡住及摩擦现象。

1.Turn the pump axle to make sure there is no block or friction of rotor before starting the pump.

2. 检查泵与管路结合是否松动。

2.Check whether the connection between pump and pipe is loosened or not.

3. 泵吸入管路底部应安装截止止回阀,确保其操作灵活。

3.Check valve should be installed in the bottom of suction pipe of pump to make sure operation is prompt.

4. 启动前,必须打开泵体顶部螺塞或放气阀,向泵内灌水,待水冒出后,再旋紧螺塞或关闭放气阀。

4.Before starting,you must open the pump body top thread plug or air-release valve.Then pour water into the pump body.After water is emitted,you must screw the thread plug or close the air-release valve.

5. 点触电动机,检查电机转向是否与泵转向标志一致。确定转向一致后,全开吸入阀,启动电机,待泵出口压力上升后逐渐调节排出阀至规定的出口压力。

5.Skimming the motor,check to see if the direction of rotation is correct. Fully open the suction valve and start the motor after the rotation to be determined consistent. Adjusting the discharge valve to the required outlet pressure after the pump outlet pressure rising gradually.

6. 停车后应关闭排出阀。在运转中若突然停电,则应先断电源,后关闭排出阀。

6.Discharge valve should be closed after cutting off the electric motor. Cut off power first, then close discharge if the electricity is cut off suddenly during the running.

7. 泵应保持在推荐的允许流量范围内运行,此范围一般为额定流量的50%-120%。

7.Pump should run in the recommendatory allowable flow range. General speaking, the range is 50%~120% rating flow.

8. 注意不要在排出阀关闭的状态下长期运转。

8.Do not let pump run for long in the circumstance of discharge valve closed.

维修保养

Maintenance

1. 应定期检查泵吸入管路中的止回阀的密封性,若因止回阀漏水或其它原因,泵内未充满水,泵启动后出口建立不起压力,则应立即停车,避免泵空转而造成损坏。

1.Check the sealing of non-return valve of pump in the suction pipe regularly.The check valve leaks,so that the pump isn’t full of water and the exit pressure isn’t existent were this to happen,you must stop running to avoid the pump is damaged on account of idling.

2. 在运转中,如发现有异常声响和振动时,应立即停车。

2.Stop the pump to check if there is any abnormity noise or vibration during operation.

3. 长期停止使用时,应打开放水螺塞,将泵内的剩水排尽。

3.Release discharge bolt to discharge the retained water if the pump will not be used for long.

4. 机械密封每半年检查一次,必要时予以更换,以保持其泄漏量≤10ml/h。

4.Mechanical sealing should be inspected once half a year. Replace them if necessary to make sure discharge is less than 10 ml/h.

六、常见故障原因及排除方法

|

故 障 |

原 因 |

解 决 方 法 |

|

1.水泵不吸水,压力表及真空表的指针在剧烈摆动。 |

注入水泵的水不够,水管或仪表漏气。 |

再往水泵内注水或拧紧堵塞漏气处。 |

|

2.水泵不吸水,真空表表示高度真空。 |

底阀没有打开,或已淤塞。吸水管阻力太大,吸水管管径太小。 |

检查或更换底阀。清洗或更改吸水管,减低吸水高度。 |

|

3.压力表显示水泵出口处是有压力,然而水仍不出水。 |

出水管阻力太大,旋转方向不对,叶轮淤塞。 |

检查或缩短出水管及检查电机转向。清洗叶轮。 |

|

4.流量低于预计值 |

水泵淤塞,密封环磨损过多。 |

清洗水泵及管道。更换密封环。 |

|

5.水泵耗费的功率过大。 |

泵轴与电机轴不在同一条中心线上。叶轮磨损。 |

调整电机与泵轴中心线。更换泵轴,更换叶轮。 |

|

6.水泵内部声音反常,水泵吸不上水。 |

流量太大,吸水管阻力过大,吸水高度过大,在吸水处有空气漏入,所输送的液体温度过高。 |

增加出水管阻力以减低流量,检查泵吸水管内阻力,检查底阀减小吸水高度。拧紧堵塞漏气处,减低液体的温度。 |

Ⅵ.Reason of Normal Failure and Solution

|

Failure |

Reason |

Solution |

|

1.Pump could not suction water. The fingers of pressure gauge and vacuum gauge swing acutely. |

The filled water is insufficiency. There is leakage in water pipe or instrument. |

Fill water to the pump or screw the leakage. |

|

2.The pump could not suction water. And the vacuum gauge shows highly vacuum condition. |

The bottom valve isn’t open or is stagnated. The resistance of suction pump is too large. The diameter of suction is too large. |

Check or replace the bottom valve. Clean or adjust suction pipe. Lower the suction water position. |

|

3. The pressure gauge shows pressure in the outlet, however, there is no water. |

Resistance in the outlet pipe is too large. The rotation direction is wrong. The impeller is stagnated. |

Check the outlet pipe or short the length. And check the running direction of electric motor. Clean the impeller. |

|

4.The capacity is less than the specified value. |

The pump is stagnated. The sealing ring wears too much. |

Clean the pump and pipe. Replace the sealing ring. |

|

5.The actual power of pump is too high. |

The pump axial and electric motor axial are not in the same line. Impeller is worn too much. |

Adjust the axial line of pump and electric motor. Replace pump axial. Replace impeller. |

|

6.Abnormal noise in the pump. Pump could not suction water. |

The capacity is too large. Resistance in the suction pipe is too large. The suction pipe position is too high. There is leakage in the suction place. The temperature of transported media is too high. |

Add the resistance in the outlet to lower the capacity. Check the resistance in the suction pipe of pump. Check the bottom valve and lower the high of suction position. Screw the leakage. Lower the temperature of liquid. |

浙公网安备 33020502000763号

浙公网安备 33020502000763号